Insulated Sheeting

Lets Keep Things Warmer

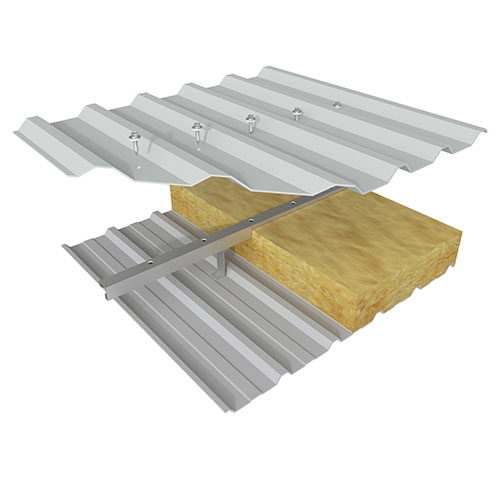

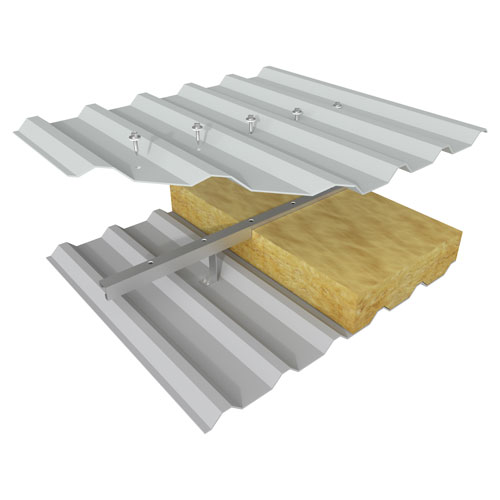

FORECLAD® - DOUBLE SKIN

This is perhaps the most commonly used application for insulating an industrial building. The use of the Foreclad metal outer sheet with its permutation of finishes and colours is complimented internally by using a bright white finished durable Foreclad metal profiled lining panel. A cavity is formed using either a bar and bracket system or a galvanised metal spacer bar to which the outer profile is fixed. This is fixed to the cladding rails with a self-tapping / self-drilling screw and nylon spacer ferrule. The liner panel, also being fixed to the rail, forms the inner skin and the resulting cavity is filled with glass fibre insulation. Increasing the cavity and introducing an air gap has the effect of a further improvement ‘U’ value.

It is also possible to use the cladding rail to act as the cavity-forming spacer. The outer sheet and liner panel are fixed to the rail’s internal and external faces and the insulation is achieved using glass fibre and the air gap formed. This has the added advantage of hiding the cladding rails internally. This is an advantage especially in food production areas where the build-up of contaminating items on horizontal surfaces can be avoided. This also allows the inner wall to be cleaned quickly and efficiently.

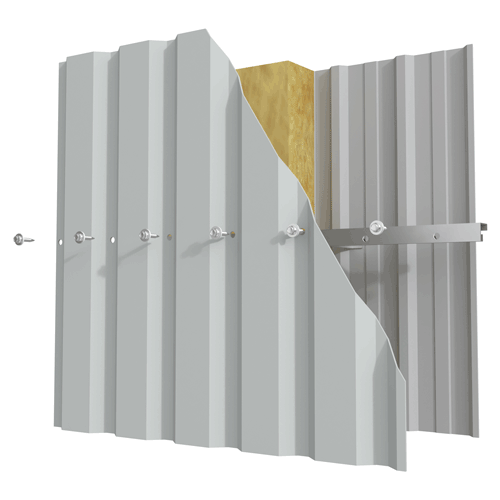

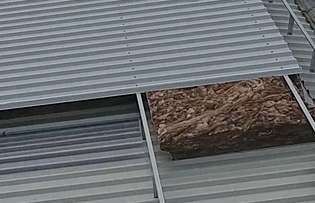

FORECLAD® - OVER CLAD

Energizing your building with an over clad is an alternative to a full roof and wall replacement which will still improve the look and condition, whilst also increasing thermal value and prolonging the life span of the building for years to come!

The process involves leaving the existing sheeting in place which helps minimize disruption to the building whilst the work is carried out. The spacer between the old skin and new skin can vary for an over clad, for example some things that can be used are timber, a bar and bracket system or our very own galvanised z spacer bar. The new top sheet using a choice of profile from our Foreclad range is available with a warranty of up to 30 years!

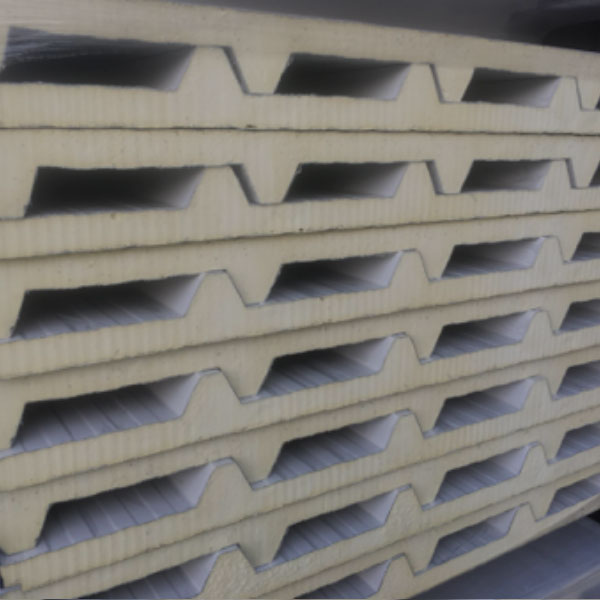

THERMOCLAD®

Thermoclad is the insulated panel system designed for covering and cladding both roofs and walls. Thermoclad, with highly prominent corrugations, far apart one from the other, has been predominantly designed for building heat insulated roofing and can be used for a wide variety of projects.

The panel has a 30mm insulation core, it is polyester paint coated on both sides and is also steel lined! Thermoclad panels help to reduce rain noise, are light weight, dramatically reduce condensation and have coated steel to both inner and outer surfaces.

- 6500mm

- 5000mm

- 4000mm

- 3050mm

THERMOCLAD IS BLOCK ENDED BOTH SIDES

AVAILABLE COLOUR: LIGHT GREY

KS1000RW

Here at Foregale we can also supply the higher grade Kingspan KS1000RW trapezoidal insulated panel. Suitable for pitched

roofs of 4º or more, It is available in various colours and insulation cores and is made to specific lengths required. As the

product is specialised it is usually on a lead time of around 2- 3 weeks from point of order. Additional details are below:

AVAILABLE COLOURS: FULL STANDARD RANGE

AVAILABLE INSULATION CORE: 40mm up to 150mm

AVAILABLE LENGTHS: CUSTOM MADE

TRISOMET

Another high grade alternative that we can also supply is the TATA Trisomet trapezoidal insulated panel. Suitable for pitched

roofs of 4º or more, It is available in various colours and insulation cores and is made to specific lengths required. As the

product is specialised it is usually on a lead time of around 2- 3 weeks from point of order. Additional details are below:

AVAILABLE COLOURS: FULL STANDARD RANGE

AVAILABLE INSULATION CORE: 40mm up to 120mm

AVAILABLE LENGTHS: CUSTOM MADE

OTHER INSULATED SHEETING

We are also able to supply various other types of insulated panels however these may be subject to special order where lead times and costs may vary. Please call our sales team for more information.

Liversedge

01924 401020

Hull

01482 640118